Natural Fresh Water Pearls Bracelet

₨8,000.00

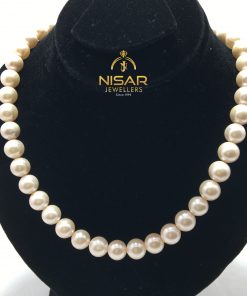

Item : Bracelet

Beads : Fresh Water Pearls

Color : White

Bracelet Size : 2.5″ Flexible

Origin : China

Certificate : No

Natural Fresh Water Pearls Bracelet

Cultured freshwater pearls are pearls that are farmed and created using freshwater mussels. These pearls are produced in Japan and the United States on a limited scale, but are now almost exclusively produced in China. The U.S. Federal Trade Commission requires that farmed freshwater pearls be referred to as “freshwater cultured pearls” in commerce. Quality of cultured freshwater pearls is evaluated through a grading system of a series of A values, based on luster, shape, surface, colour and matching.

Pearls gathered in the wild from the Holarctic saltwater pearl mussel were important sources of pearls for modern jewelry, with Scotland a major source; this species is now endangered in most areas. Although the Japanese freshwater pearl industry has nearly ceased to exist, it has a normal historic place as the first country to cultivate whole freshwater pearls, which it did in Lake Biwa, using the Biwa pearly. The industry attempted a comeback with a mussel hybrid in Lake Kasumigaura in the last decade, but this venture also met with failure, with production ceasing in 2006. The pearl farm in Tennessee also holds special historic value as it is the only freshwater pearl outside of Asia. Founded by the late John Latendresse, it continues as a tourist attraction. Today China is the only commercial producer of freshwater pearls, producing 1500 tons (2005) using the tetragon shell mussel and several hybrids that have shown heterosis from several mussel species.

Freshwater pearl harvests are typically bought while still in the shell. After harvest the pearls are delivered to a first-stage factory, which is responsible for cleaning and sorting the pearls by size and shape. After this process has been completed, the pearls are considered ready material for processing factories. The pearls are pre-treated (maeshori) in a warm and cold chemical solution and then bleached. The pearls that exhibit strong coloration only go through the maeshori and are not bleached or dyed.

After the pearls are treated, they are drilled and then polished with a mixture of cornmeal and wax. Finally they are matched into temporary strands, which are then matched again into hanks. Hanks are composed of 5 to 10 temporary strands and are considered wholesale-ready.

Be the first to review “Natural Fresh Water Pearls Bracelet” Cancel reply

Related products

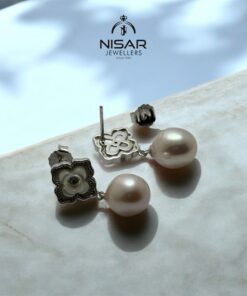

Ear Accessories

Pearls Jewellery

Ear Accessories

Pearls Jewellery

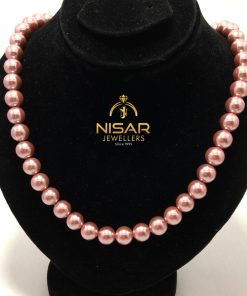

Pearls Jewellery

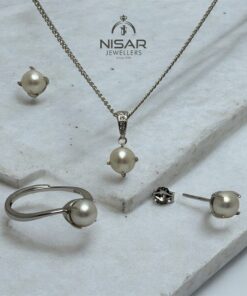

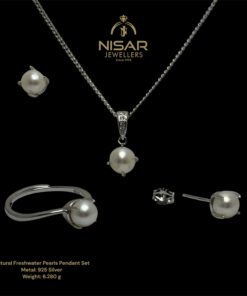

Pendant Sets

Pearls Jewellery

Pearls Jewellery

Reviews

There are no reviews yet.